Dini Têxtil serves industries in all segments with high technology, developing products with a commitment to quality and following the technical standards demanded by the market.

Dini Têxtil serves industries in all segments with high technology, developing products with a commitment to quality and following the technical standards demanded by the market.

The textile industry has its own particularities in each segment it operates in.

Not unlike the automotive industry, we work with customizations according to the style and personality of each O&M, meeting technical requirements with quality and comfort.

In this very competitive segment, where we are the only national company, we stand out for our innovation, providing solutions for the most diverse applications such as permanent virucidal fabrics, flame retardants (meeting the strictest standards, such as FAR 25.582 used for aircraft), lighter fabrics, thermal fabrics to improve vehicle efficiency.

Technology and sustainability come together to meet a competitive market in a disruptive way.

In addition to product development, active participation in the plastics chain with a high degree of interaction with all the players.

Dini Têxtil has always been at the forefront of research into fabrics and technologies that cater to this public, which requires extreme care.

The fabrics created always take into account safety for children’s use, along with technologies that make everyday life easier for those responsible for maintaining strollers and restraint chairs.

We create fabrics with inherent technologies and finishes that meet the safety standards demanded by the market and we are always looking to innovate, so that this market has new features and is aligned with consumer demands.

We manufacture special polyester yarns with various functionalities:

– 100% Post-Consumer Recycled PES Yarn (ELEVA®) where we remove 200 bottles and save 80 liters of water for every Kg of yarn produced.

– 100% recycled PES/graphene yarn (Ecographe®): With all the above properties plus mechanical and thermal properties;

– PES/Graphene yarn (VittaGraphe®): Mechanical / thermal / Virucidal properties;

– PES/Ceramic wires: Fire-retardant properties;

– PES yarn: Biodegradable

All our yarns are dyed in the mass, which gives greater color uniformity, greater solidity and an Ecofriendly process, without using water.

DINI TÊXTIL has developed a range of hospital fabrics and products that combine protection, comfort and durability.

The fabrics have been developed using the latest technology, including the VITTAV antiviral treated yarn, which has proven viral efficiency while maintaining all the mechanical properties and UV resistance of a mass dyeing process.

All the antiviral and bactericidal properties are permanent in the fabric, even when subjected to industrial cleaning.

In addition to fabrics that offer protection and excellent comfort, DINI TÊXTIL products offer high durability and resist the chemical and mechanical processes inherent in industrial laundry processes.

The trims and seams of the products follow a high standard of quality, so they don’t get damaged during the washing processes carried out in industrial laundries.

Application: this product replaces disposable gowns in operating rooms, hospital premises and clinics.

Product can be reused for at least 50 industrial sanitizations, with high durability and excellent user comfort.

More sustainable product (does not harm the environment, as is the case with disposable gowns, which have to be disposed of as contaminated material, requiring incineration and environmental documentation of disposal.

Developed in material that can be cleaned in industrial laundries, it is distinguished by the durability of the fabrics, excellent tensile strength, high color fastness and practicality in the industrial process.

The product has nickel-plated brass eyelets (they won’t rust), reinforced seams, high-strength fabric and white, blue and light green fabrics, and is used in hospital ICUs as bed dividers.

Product developed in kettensthul mesh, with high durability in industrial laundries, facilitating the process within laundries, in which they are used to separate different parts within the machines, preserve less resistant products and prevent smaller parts from escaping within the industrial operation.

Material developed with a high-strength polyester cord closure system, sealed ends and easy handling when closing and opening the bag.

Technologies that continually evolve to meet the growing demands of the security market.

Dini Têxtil has technologies that are continually evolving to meet the growing demands of the Security market, helping suppliers to produce garments and equipment that are at the forefront of the evolution required in this segment.

Fabrics with inherent technology or differentiated finishes are present in the following areas:

Fabrics supplied with finishes that meet the needs of the growing private security market, which requires solutions with competitive prices and technology compatible with their use.

Dini Têxtil is developing products with elasticity and finishes that cater for people who wear professional uniforms on a daily basis and need comfort, durability and safety.

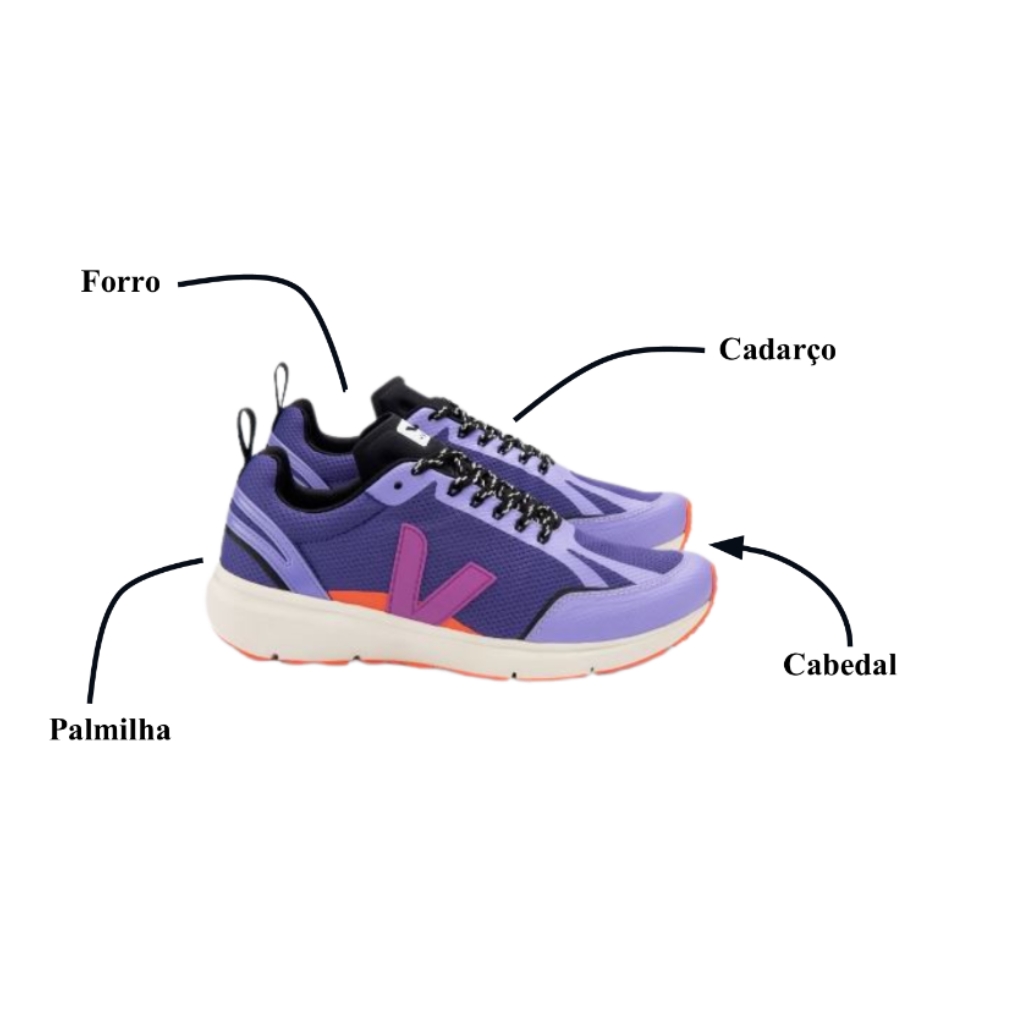

Safety shoes need fabrics that meet the standards required for the production of PPE and that guarantee those who use the product the necessary safety, without taking time off work due to unnecessary accidents.

Covers for ballistic vests, belts, holsters, helmets, among other possibilities, are made from fabrics produced with high tenacity yarns, differentiated weaves and technological finishes that together make the products allied to the needs of use, with high resistance, comfort and durability.

The line of high tenacity fabrics, produced with polyamide 6.6, guarantee the color fastness required for military uniforms, combined with comfort and technologies that prevent unwanted odors, along with durability.

Military footwear uses fabrics with odor-resistant finishes and high breathability. Dini Têxtil fabrics can serve this market with all the quality and technology required, respecting different uses and requests.

Backpacks, tents, camp beds, among others, can be produced with fabrics made from high tenacity yarns, ensuring that they are resistant to the activities carried out and have the durability to give the products the quality that the manufacturer values for their brand.

Mountaineering and cycling are growing segments that require fabrics that are inherently high-tech, can be used for hours at a time and don’t cause discomfort to those practicing the sports. Dini Têxtil fabrics guarantee the useful life of equipment and clothing so that no accidents or setbacks occur during the period of use.

Operating in the market for more than 30 years, Dini Têxtil has vast experience in producing fabrics for various segments.

The company is ISO 9001 and ISO 14001 certified, guaranteeing the quality of its products and processes.

Commitment to continuous improvement aimed at preventing environmental pollution.

The company offers a personalized and dedicated service to its clients, helping them choose the best fabrics for each project.

Dini Têxtil offers high-quality products at competitive prices.

The company is committed to social responsibility and develops actions that contribute to the well-being of the community.

© 2024 Desenvolvido por Wiaweb Webmasters

No que podemos te ajudar?